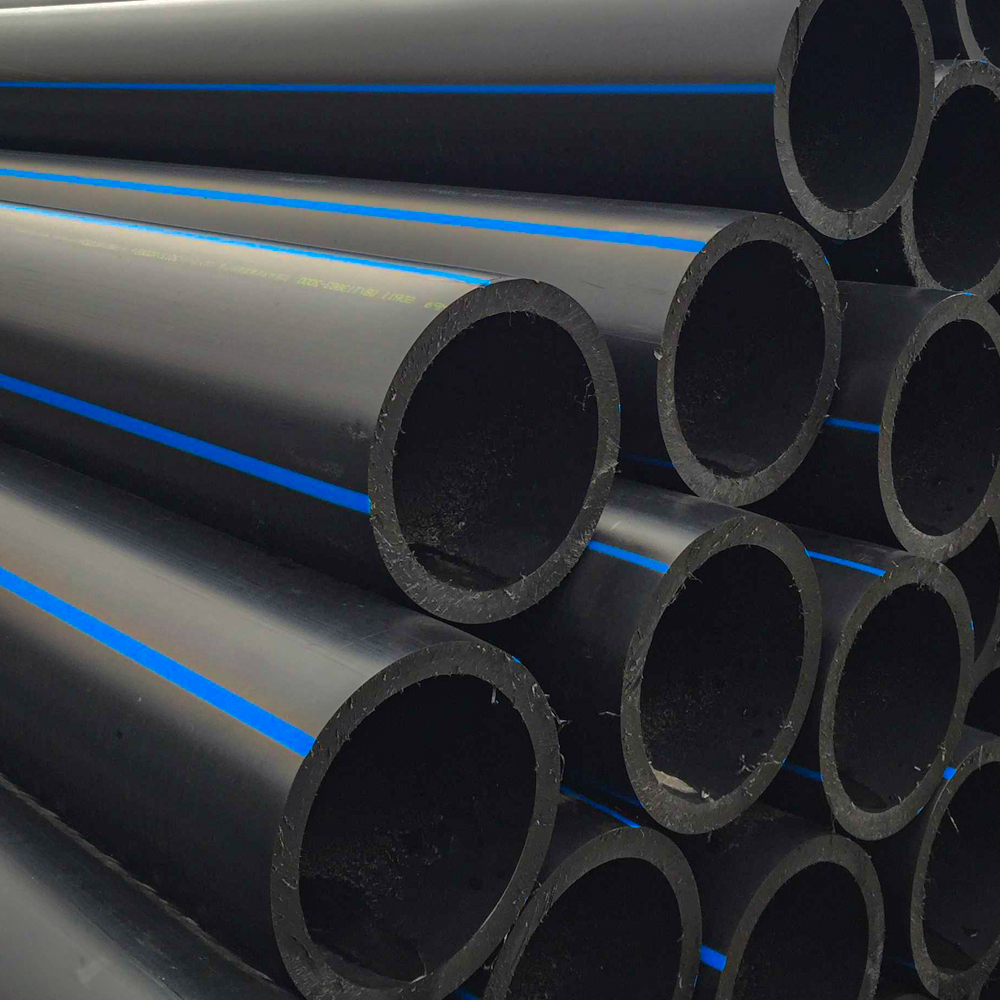

Octal Pipes pressure are manufactured with ISO 4427 Specification.

Application:

- Urban tap water pipe network system.

- Industrial raw material conveying pipeline system

- Landscaping water supply network system

- Sewage water system

- Ore slurry transport system

- Irrigation pipe system